OFFSHORE STRUCTURE PIPE

Offshore Project

Offshore Structural Pipe

Offshore platform is the equipment to drill and extract oil from the sea. Based on different functions, offshore platform can be classified as drilling platform, production platform, service platform, oil storage, etc. There are bottom-supported, gravity, jack-up, semi-submersible, tension leg type, etc. According to different function, Pile foundation type, bottom-supported and gravity platform are used in shallow waters. Jack-up, semi-submersible, tension leg type, such as vertical cylinder type of offshore platform become the hotspot in the field of ocean engineering.

We has developed the offshore structural pipes for offshore platform, supplied in normalized or quenched and tempered condition for yield strength 355~690 MPa.

– Bracing pipe

– Chord pipe

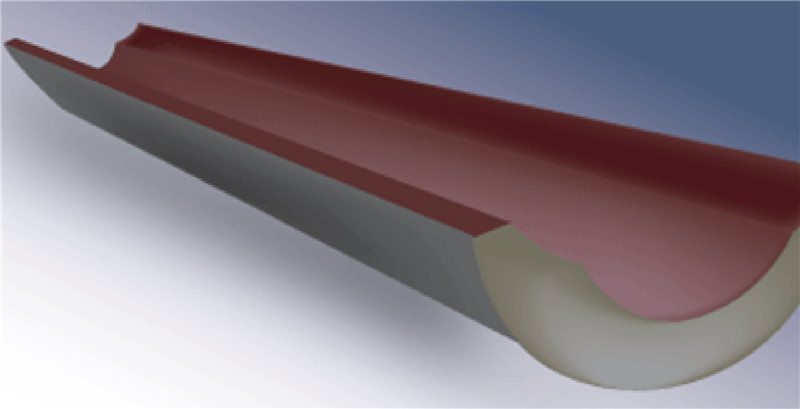

Jack-up drilling platform leg chord pipe is manufactured as with semicircle.

Its advantage is low cost and high efficiency that producing semicircle pipe with seamless pipe through longitudinal cutting process.

Characteristics of we products

– Steel design with low carbon and micro alloyed

– Low carbon equivalent

– Excellent weldability

– Excellent low temperature toughness

– Lower ductile brittle transition

– Higher surface quality

Reference Standards

API SPEC 5L Specification for Line Pipe

EN 10210-1 Hot finished structural hollow sections of non-alloy and fine grain steels – Part 1:

Technical delivery conditions.

EN 10210-2 Hot finished structural hollow sections of non-alloy and fine grain steels – Part 2:

Tolerances, dimensions and sectional properties.

EN 10225 Weldable structural steels for fixed offshore structures – Technical delivery conditions

ABS RULES Material and Welding 2015 Part 2

ABS RULES Building and Classing Mobile Offshore Drilling units 2015 Part 3

DNV-OS-B101

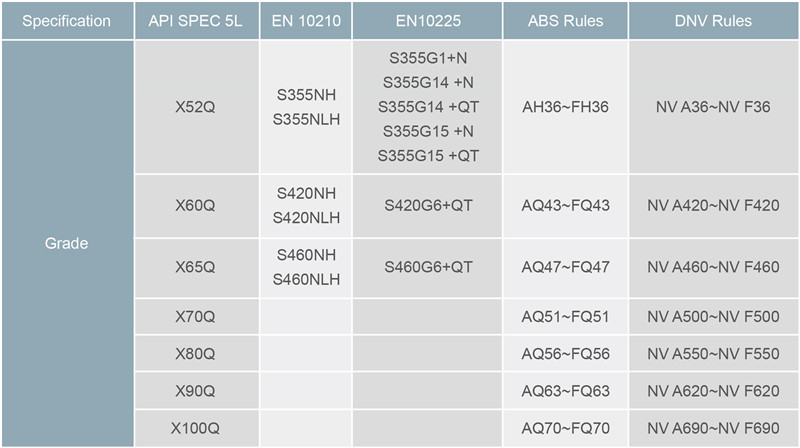

Grades of Pipes for Offshore Structures

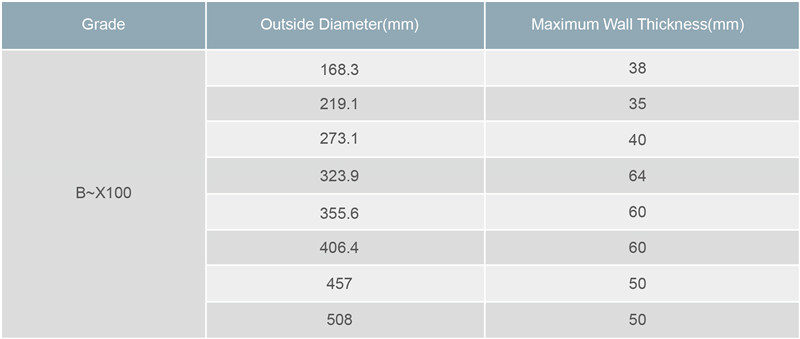

Size range

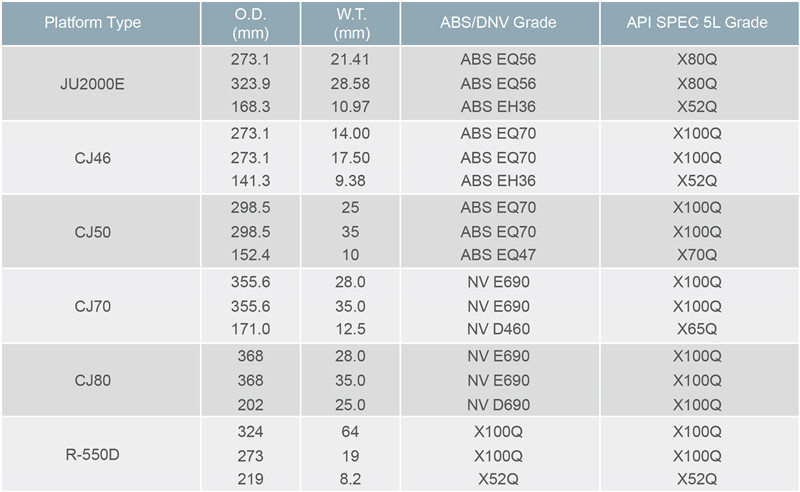

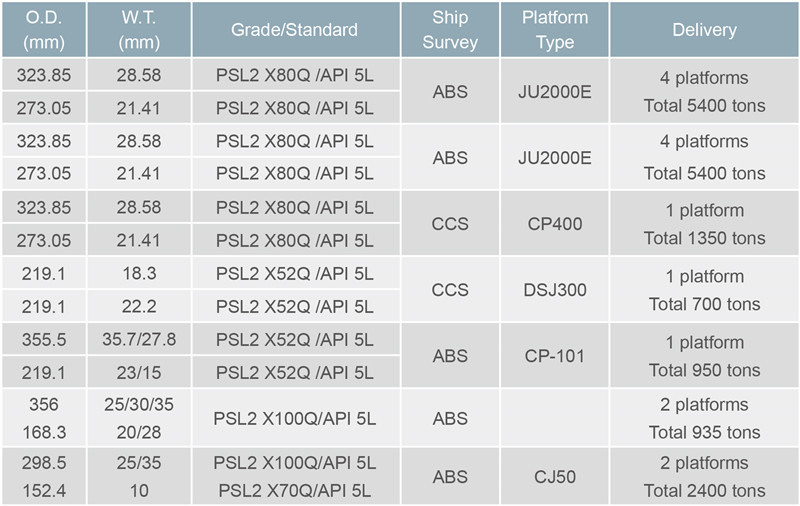

Platform Type and Corresponding Pipe Sizes and Grades

Mechanical Properties

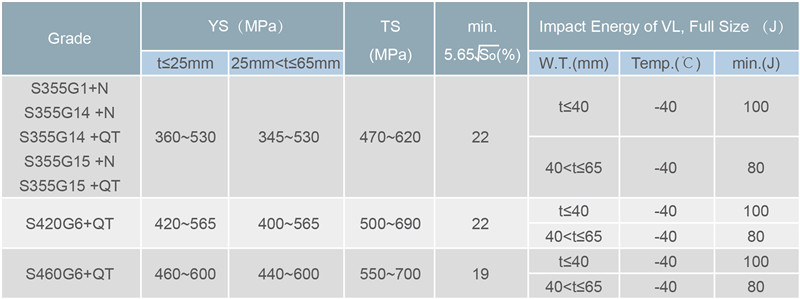

Performance Data as per EN 10225

note:t = wall thickness

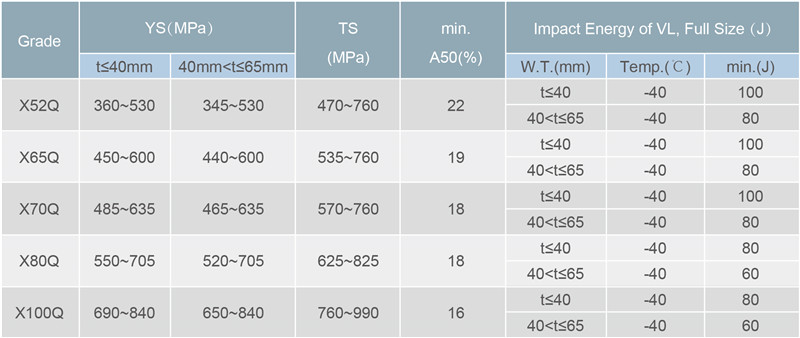

Performance Data as per API SPEC 5L

note:t = wall thickness

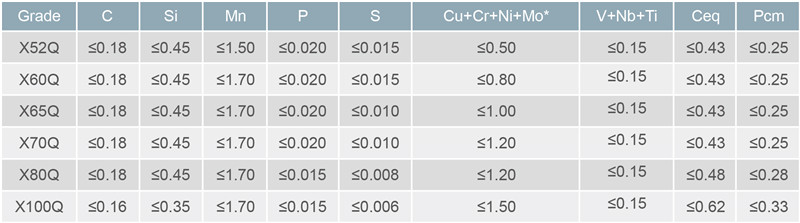

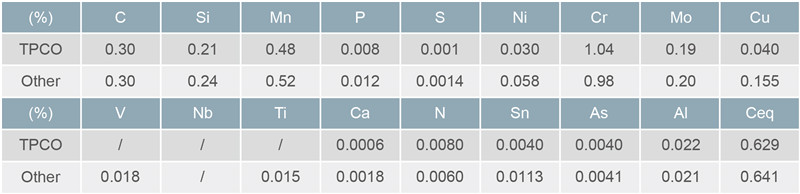

Chemical Composition (%, API Spec 5L)

other technical requirement as per API SPEC 5L and Customer’s requirement.

Customer Weldability

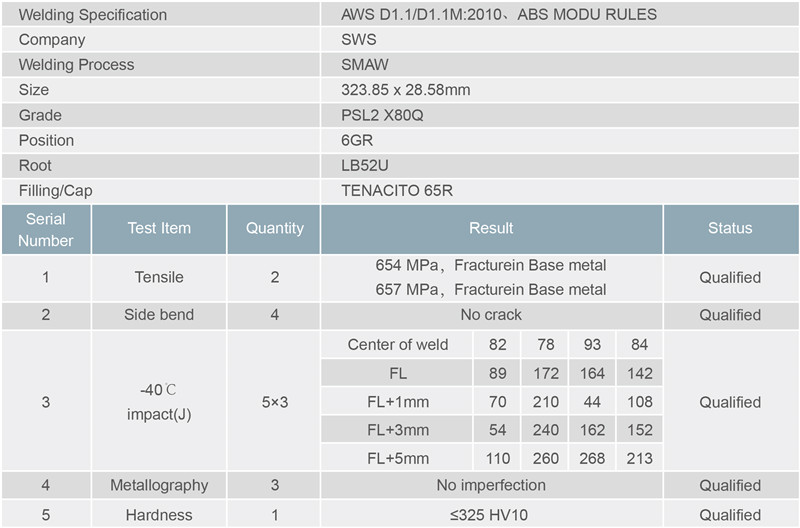

X80Q Weldability test

X100Q Weldability

Currently, products from X70Q to X100Q have passed weldability evaluation by Singapore Keppel.

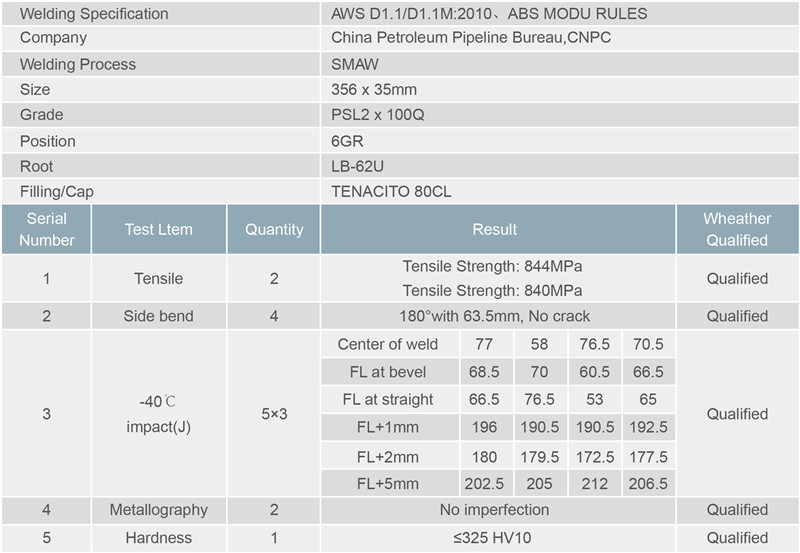

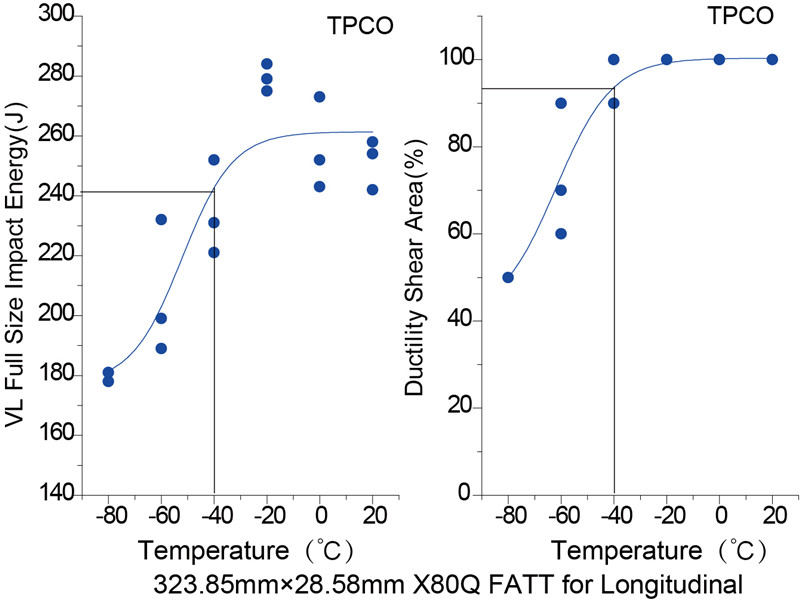

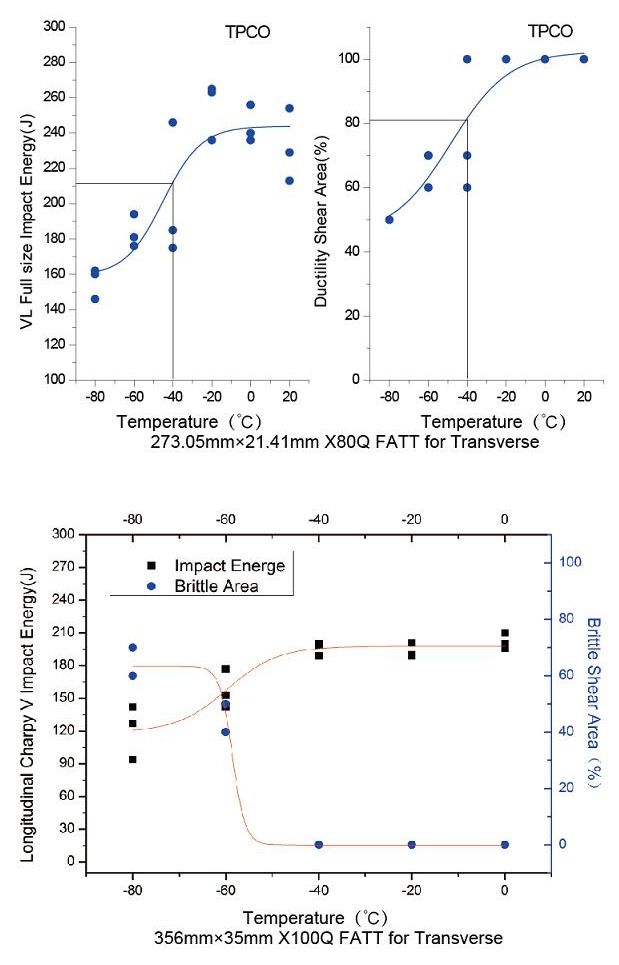

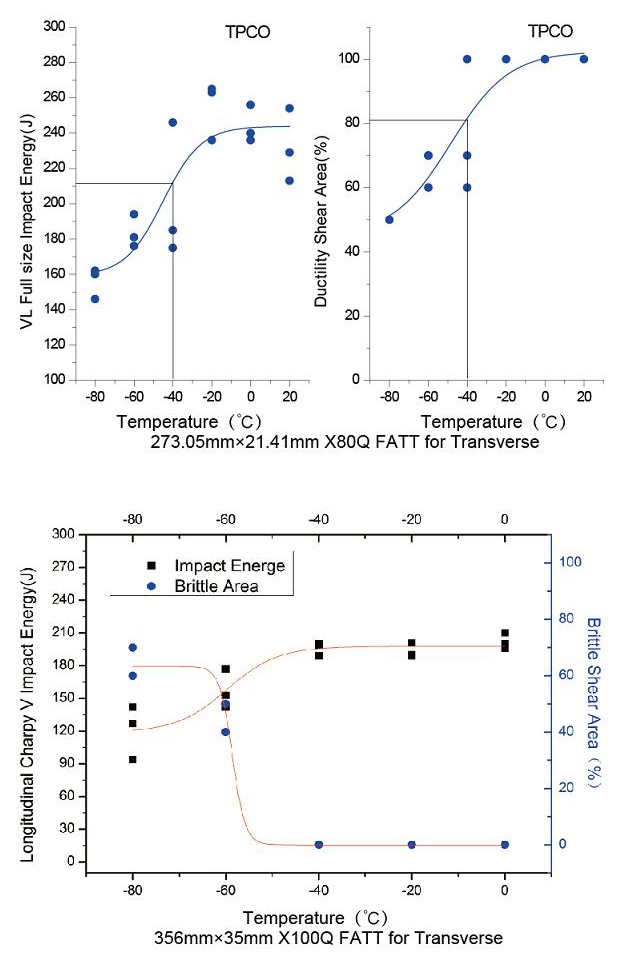

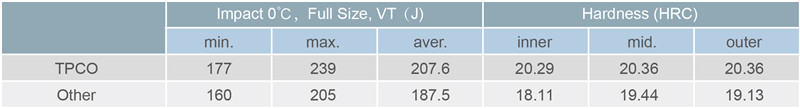

Ductile Brittle Transition

Conclusion: The impact toughness of the product is good. The temperature of ductile-to-brittle transition is lower than -40°C for X100Q and -80°C for X80Q. Therefore, they are safer when used in low-temperature environments.

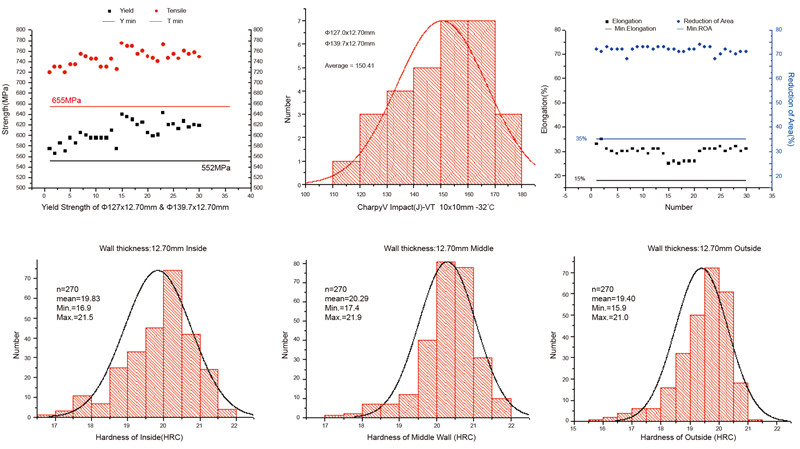

Manufacturing Statistics X80Q – X100Q

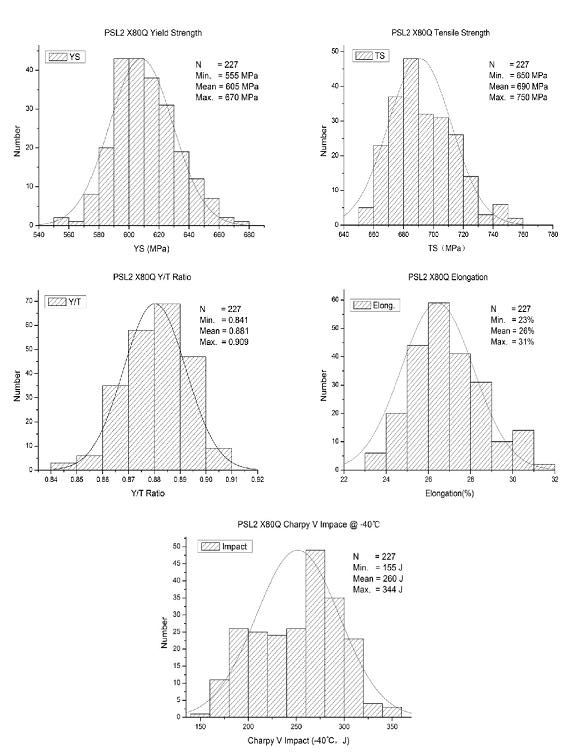

Production Statistics X80Q

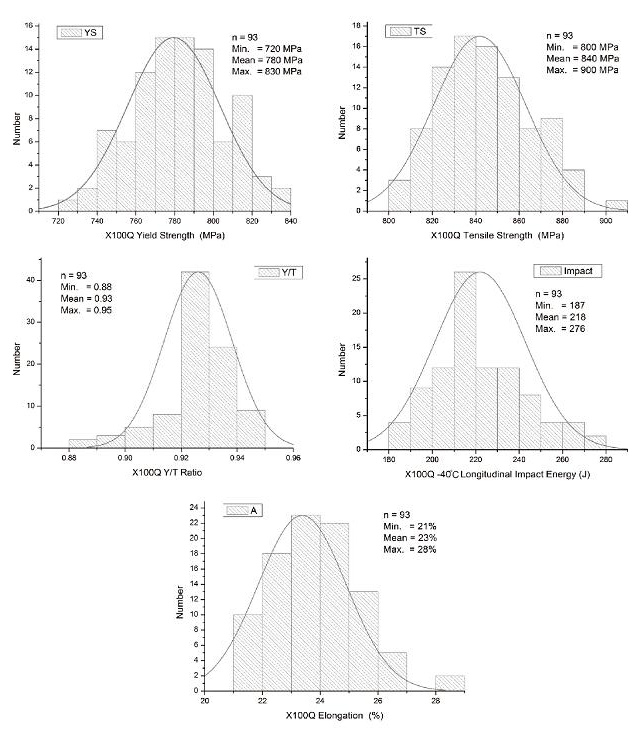

Production Statistics X100Q

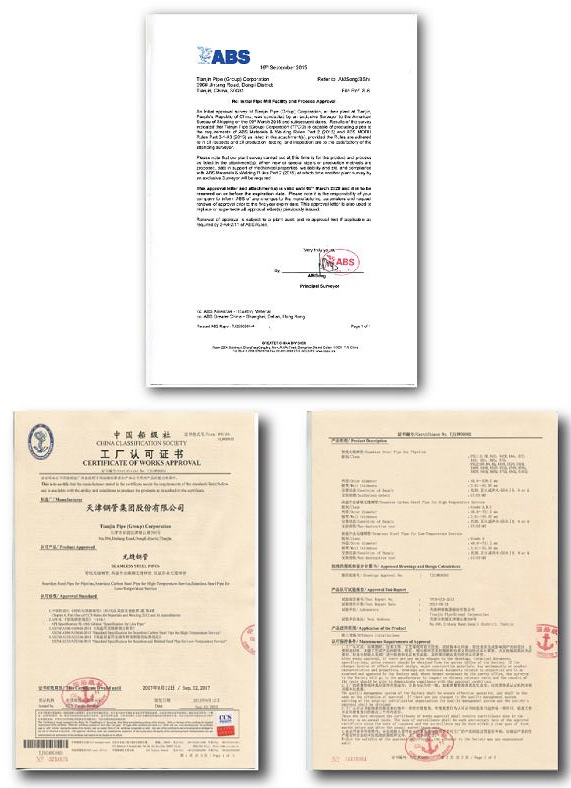

Certification of Offshore Structural Pipe

Construction Site Pictures

Supply Record of Jack-up Drilling Platform Pipe

Choke & kill, Boost Pipe

Choke & Kill, Boost pipe should be produced in accordance with ASTM A519 and A370, latest editions. API 16C and API spec 5L shall be used as a reference only. Material shall comply with NACE MR-01-75(ISO 15156-2).

Chemical Composition as per 4130 of ASTM A 519

Mechanical Property

Manufacturing Statistics